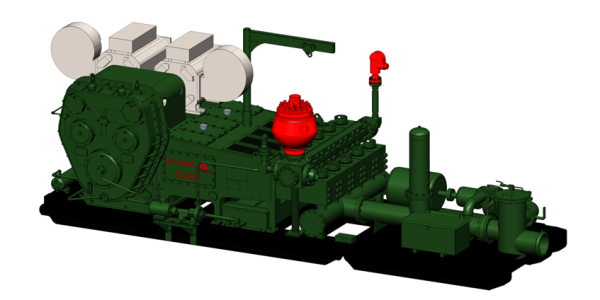

Finite Element Analyzed Design

The mud pump housing is optimized by finite element design, improving structure and strength more reliable.

Strict Process Control

Semifinished high-pressure parts are inspected by UT, MT and other NDT, guaranteeing the reliability and safety of parts.

Integral Forging for Key Transmission Parts (crank, gear shaft)

The gear shaft and crank are made of alloy steel under integral forging, guaranteeing high strength and large bearing load.

The quality balance of products processed by integral forging is much better than that of products processed by casting or welding, and the advantage of dynamic balance effect during operation is obvious.

Easy Replacement for Cylinder Liner and Piston

Clamp connection is for intermediate rod, piston rod and cylinder liner, reliable connection and easier connection than thread in cylinder liner replacement.

Easy Replacement for Valve and Valve Seat

L-type hydraulic cylinder arrangement allows individual operation of input cylinder valve and valve seat, which lead to convenient and faster replacement.

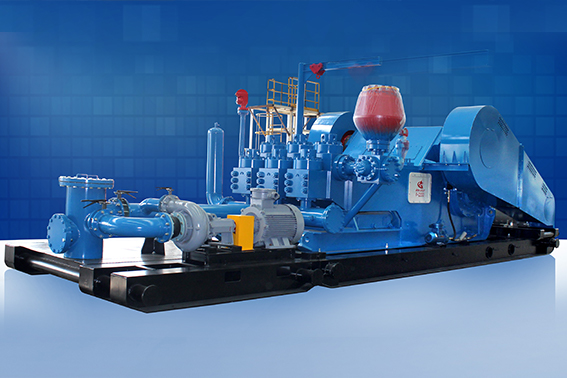

Large Discharge, High Pressure and Wide Application

Designed working pressure up to 52MPa with max discharge of 4679L/m, satisfying the requirements of land and offshore deep well drilling in high-pressure and large discharge mud pump for technology.

Even and Stable Flow, Small Pressure Fluctuation and Low Vibration

Three-cylinder pump cranks form 120 ° three flow sinusoidal curves. Flow superposition leads to even and stable flow, small pressure fluctuation and low vibration.

Compact Size for Convenient for Transportation

Optimized structural design make the pump body compact to satisfy requirements of road transportation.

Both Metric and Imperial Cylinder Liner Are Available

Both metric and imperial cylinder liner are available, satisfying requirements from customers at home and abroad.